Increase Performance: Just How Updating Undercarriage Parts Can Boost Performance

Increase Performance: Just How Updating Undercarriage Parts Can Boost Performance

Blog Article

Discover Undercarriage Parts for Heavy Equipment

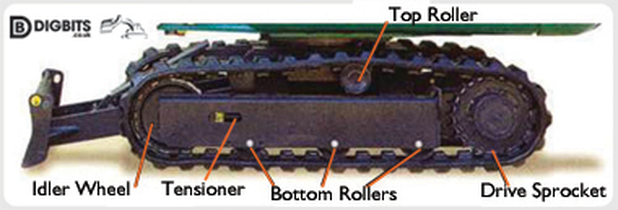

Recognizing the ins and outs of undercarriage parts is crucial for the ideal performance and longevity of hefty machinery. From track shoes to rollers, idlers, and sprockets, each element plays a vital role in the capability of the equipment.

Value of Undercarriage Components

The undercarriage parts of hefty equipment play an important role in guaranteeing the total performance and longevity of the equipment. These elements, including tracks, rollers, chains, gears, and idlers, create the structure whereupon the machine operates. A well-kept undercarriage not just offers stability and assistance to the hefty equipment however likewise adds dramatically to its operational efficiency and productivity.

Among the vital advantages of investing in high-grade undercarriage parts is the reduction of downtime and maintenance expenses. By utilizing sturdy elements that can withstand the rigors of durable applications, drivers can decrease the need for constant repairs and substitutes, hence taking full advantage of the machine's uptime and general life-span.

Additionally, appropriately operating undercarriage components ensure optimal weight circulation, maneuverability, and traction, permitting the hefty machinery to operate smoothly even in tough terrains. This dependability is essential for industries such as building and construction, agriculture, and mining, where devices performance straight impacts task timelines and productivity. In verdict, the value of undercarriage parts can not be overemphasized in maintaining the performance and durability of hefty equipment.

Sorts Of Track Shoes

When taking into consideration the different sorts of track footwear for heavy equipment, it is important to assess their layout and performance in connection with certain operational demands. Track shoes are critical elements of the undercarriage system, providing weight, grip, and stability distribution for heavy equipment such as excavators, bulldozers, and crawler cranes.

One of the most common kinds of track shoes include:

** Grouser Shoes **: Featuring increased metal bars (grousers) along the footwear's surface, these track footwear offer boosted traction in difficult terrains like mud, snow, and loosened gravel. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser footwear however with an extra set of grousers, these track shoes offer also higher traction and stability, making them perfect for incredibly rough surfaces.

** Three-way Grouser Shoes **: With three sets of grousers, these track footwear supply optimal traction and stability, making them suitable for the most demanding problems.

Picking the appropriate her comment is here sort of track footwear is crucial for optimizing the performance and longevity of heavy machinery while making certain safety and efficiency during procedures.

Feature of Rollers and Idlers

Rollers and idlers play important duties in sustaining and assisting the track shoes of hefty machinery throughout operation. By stopping excessive slack or rigidity in the tracks, idlers contribute to the general security and performance of the equipment.

Furthermore, idlers and rollers work with each other to maintain the track footwear in alignment, preventing them from sliding or hindering off throughout operation. Effectively working idlers and rollers are vital for ensuring the durability of the undercarriage system and making best use of the maker's performance. Regular maintenance and evaluation of these elements are essential to identify any type of indications of wear or damages beforehand, avoiding expensive repair services and downtime in the future.

Duty of Gears in Equipment

Maintenance Tips for Undercarriage Elements

Effective upkeep of undercarriage elements is important for making sure the longevity and optimal efficiency of hefty equipment. Normal inspection of undercarriage parts such as track chains, rollers, idlers, gears, click here for info and track footwear is crucial to protect against unanticipated failures and costly repairs. It is also important to make sure appropriate track stress to protect against premature wear on parts.

Final Thought

To try here conclude, the undercarriage components of hefty equipment play a critical role in ensuring the smooth performance and longevity of the tools. Recognizing the relevance of track footwear, gears, idlers, and rollers, along with applying appropriate maintenance methods, can greatly influence the total performance and efficiency of the machinery (undercarriage parts). Regular assessment and prompt replacement of damaged parts are important in maximizing the lifespan and productivity of hefty equipment

Rollers and idlers play essential functions in supporting and assisting the track shoes of heavy equipment throughout procedure.In heavy equipment, gears serve a critical function in transferring power from the engine to the tracks, making it possible for the equipment to relocate efficiently and properly. These parts are connected to the axles or last drives of the machinery and work in combination with the tracks to push the devices ahead or backward. Normal inspection of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is vital to protect against expensive repairs and unanticipated break downs. Understanding the importance of track footwear, rollers, idlers, and gears, as well as carrying out proper upkeep techniques, can considerably influence the overall efficiency and performance of the equipment.

Report this page